Manufacturing facility design and location are critical for operational efficiency. Real estate choices consider product type, raw material access, utility availability, and logistics. Layouts must accommodate machinery, workflow, and quality control, with flexible designs supporting continuous improvement through advanced technology and data insights, ultimately maximizing productivity and success.

Manufacturing facilities are more than just production lines; they’re complex ecosystems demanding specialized features. From raw material handling to finished goods storage, each stage necessitates tailored spaces. Understanding these unique needs is paramount for optimizing operations. This article explores crucial aspects, including real estate considerations and design strategies that enhance efficiency and foster innovation within these specialized landscapes.

Understanding Unique Manufacturing Facility Needs

Manufacturing facilities come in a wide array, each with its own set of specialized requirements driven by the products they manufacture and their unique operational needs. When considering the ideal location for a manufacturing facility, understanding these specific demands is paramount. Factors such as space requirements, utility access, proximity to raw material sources, and logistics considerations play a significant role in shaping the perfect real estate choice.

For instance, facilities producing bulky items necessitate ample floor space, while those involving intricate assembly processes may require specialized equipment for loading and unloading. Efficient layout design, clear heights, and adequate loading docks are essential features that cater to these unique needs, ensuring smooth operations and maximizing productivity.

Real Estate Considerations for Specialized Layouts

When designing and building manufacturing facilities with specialized features, real estate considerations are paramount. The layout of the facility must accommodate specific machinery, workflow processes, and quality control measures unique to the production tasks at hand. Therefore, choosing the right location is crucial; proximity to raw materials sources, transportation hubs, or skilled labor markets can significantly impact operational efficiency and cost-effectiveness.

Real estate experts play a vital role in identifying sites that offer not just affordable land prices, but also ample space for expansion, essential infrastructure, and zoning regulations conducive to manufacturing operations. Factors like local environmental conditions and accessibility for heavy equipment must also be taken into account. This strategic approach ensures that the facility layout aligns with production needs, enabling optimized workflows and ultimately contributing to the success of the manufacturing enterprise.

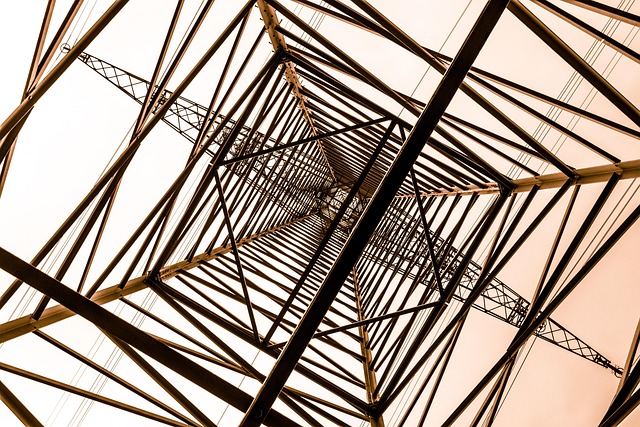

Designing Spaces that Foster Efficiency and Innovation

Manufacturing facilities are more than just buildings; they’re complex ecosystems designed to optimize production processes. When crafting these spaces, prioritizing efficiency and innovation is paramount. This involves strategic planning in real estate to maximize workflow and minimize downtime. Layouts should encourage collaboration among teams while ensuring raw materials and finished goods move seamlessly throughout the facility.

Incorporating flexible design elements allows for adaptable workspaces that can accommodate changing production needs. Advanced technology, such as automated systems and smart sensors, plays a crucial role in enhancing efficiency by providing real-time data on inventory levels, equipment performance, and workforce productivity. This enables manufacturers to make informed decisions, streamline operations, and foster a culture of continuous improvement.